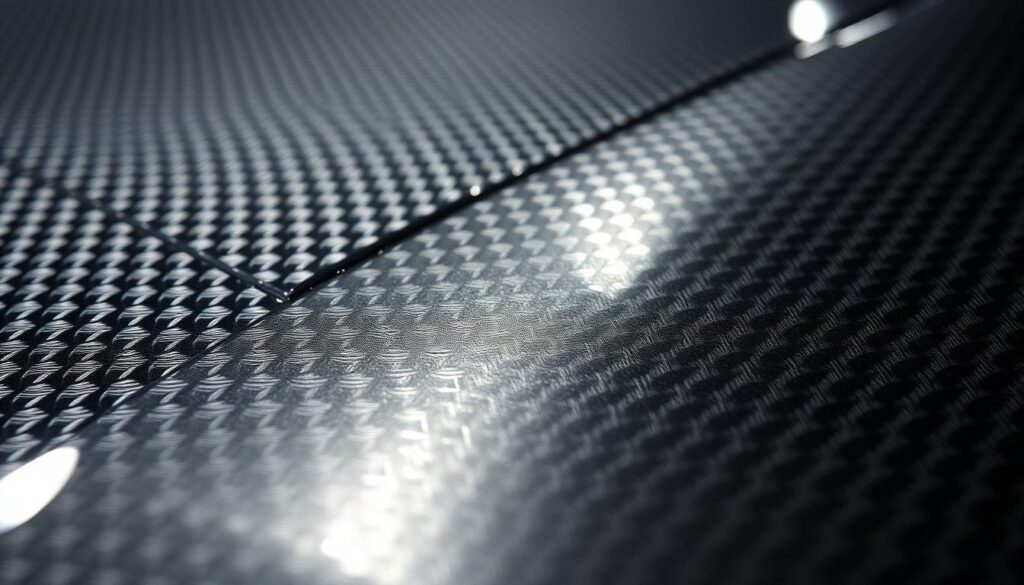

Why is Carbon Fiber So Expensive on Cars? You’ve probably seen the sleek designs and high performance of cars with carbon fiber parts. But you’ve also wondered why they cost so much.

Carbon fiber in cars is pricey because of the complex making process. It also needs high-quality materials.

Learning about the cost of carbon fiber in cars is key. This article will explain why it’s so expensive.

What is Carbon Fiber?

Carbon fiber is a material made from carbon atoms. These atoms are bonded together in crystals. This makes carbon fiber very strong and durable.

It’s not just for fancy sports cars. Carbon fiber is also used in aerospace, sports gear, and medical devices.

So, how is carbon fiber made? It starts with a material called polyacrylonitrile (PAN). This material is then stretched and heated to high temperatures. This process, called pyrolysis, removes non-carbon atoms, leaving behind a chain of carbon atoms.

This chain of carbon atoms is what makes carbon fiber so strong and light. It’s perfect for places where you need to save weight, like in planes and fast cars. Carbon fiber is not just light; it also stays strong even when stressed.

Knowing how carbon fiber is made helps us see its value. Making it is complex and expensive. But, its benefits are worth it in many fields. As technology gets better, making carbon fiber might become cheaper and more available.

Why is Carbon Fiber So Expensive on Cars?

Car makers choose carbon fiber for its special qualities, even though it’s pricey. Its unique properties and the hard work needed to make it are key reasons.

Carbon fiber comes from polyacrylonitrile (PAN), a man-made material. Making it into the strong, light material for cars is a tough process. The cost of PAN is a big part of the expense.

Creating carbon fiber is a detailed process. It involves spinning, stabilizing, carbonizing, and treating the surface. Each step needs careful work and special tools, raising the price.

The hard work needed to work with carbon fiber also adds to the cost.

Using carbon fiber requires skilled workers. They lay out the material, apply resin, and cure it under high pressure and heat. This process is slow and needs a lot of skill.

Cost Breakdown of Carbon Fiber Production

| Production Stage | Cost Factor | Percentage of Total Cost |

|---|---|---|

| Raw Materials | High cost of PAN and other chemicals | 30% |

| Manufacturing Process | Labor and equipment costs | 40% |

| Labor and Application | Skilled labor and time-consuming application | 30% |

Even with the high costs, carbon fiber’s benefits make it worth it. It’s strong yet light, which helps cars go faster and use less fuel.

Carbon fiber does more than just save weight. It also makes cars safer and more durable. It can handle a lot of stress and heat, making it a top choice for cars.

In short, the price of carbon fiber is worth it for its many benefits. As technology gets better, making it might become cheaper, making it more common in cars.

The Performance Benefits of Carbon Fiber

Carbon fiber is a game-changer for car performance. It boosts power-to-weight ratio, speed, and fuel use. Its secret? It’s both super light and incredibly strong.

Carbon fiber’s main perk is its ability to cut down a car’s weight. By using it in body parts and chassis, cars get lighter without losing strength or safety. This means cars can speed up and stop faster, making driving more fun.

But carbon fiber does more than just make cars faster. It also makes them more fuel-efficient. A lighter car needs less energy to move, so it uses less gas. This is great for drivers who want to save on gas without losing speed.

Key Performance Benefits

- Enhanced Power-to-Weight Ratio: Carbon fiber makes cars lighter, making them more agile and quick.

- Improved Acceleration: Its lightness means cars can speed up faster, giving drivers a thrill.

- Better Fuel Efficiency: With less weight, cars use less gas, saving money and the environment.

Carbon fiber’s effect on car performance is clear. As car makers keep using carbon fiber applications, we’ll see even more cool uses of this material.

Carbon Fiber Applications in Modern Vehicles

Modern cars are using carbon fiber more and more. It’s great because it’s light but strong. This makes it perfect for many car parts.

Body Panels and Chassis

Carbon fiber is key in body panels and chassis. It’s strong but light, which helps cars use less fuel and drive better. Brands like BMW and Lamborghini are already using it.

Carbon fiber is also in car interiors, like dashboards and seats. It makes the inside feel fancy and helps the car weigh less. Luxury cars are using it more and more.

The table below shows how carbon fiber is used in cars:

| Application | Benefits | Examples |

|---|---|---|

| Body Panels | Reduced weight, improved fuel efficiency | BMW i8, Lamborghini Huracan |

| Chassis | Enhanced structural integrity, better handling | Mercedes-AMG, Ferrari LaFerrari |

| Interior Elements | Premium feel, weight reduction | Dashboard trim, carbon fiber seats |

The car world is always changing, and carbon fiber will play a bigger role. Its special qualities make it a top choice for car makers wanting to make their vehicles better.

Conclusion: Why is Carbon Fiber So Expensive on Cars?

You’ve learned about carbon fiber’s benefits in cars. Now, you might wonder if it’s worth the price. Its strength, resistance to corrosion, and design flexibility make it appealing to car makers.

The high cost of carbon fiber might seem like a barrier. Yet, its benefits can make driving better. It can make cars lighter, which improves fuel use and handling. Plus, it lasts longer, saving on repairs.

Thinking about a car with carbon fiber parts? Consider its pros and cons. If you want better performance, efficiency, and style, it might be worth it. As car tech advances, carbon fiber will become more common and affordable.

See Also: Why Is The UK So Bad At Basketball?

FAQ

What is carbon fiber, and how is it made?

Carbon fiber is a strong, light material made from carbon atoms. It’s made by creating precursor materials, stretching, and heating them.

Why is carbon fiber so expensive to use in cars?

Carbon fiber costs a lot because of the pricey raw materials and complex making process. It also takes a lot of work to handle.

What are the benefits of using carbon fiber in vehicles?

Using carbon fiber in cars offers many benefits. It’s strong, light, and helps cars go faster and use less fuel.

How is carbon fiber used in modern vehicles?

Today, carbon fiber is used in many parts of cars. This includes body panels, chassis, and even interior parts like dashboards and seats. It makes cars lighter and feel more luxurious.

Is carbon fiber worth the cost for my vehicle?

Whether carbon fiber is worth it depends on what you need. If you want your car to perform better, it might be a good choice.

Can carbon fiber be used in mass-produced vehicles?

Yes, car makers are trying to make carbon fiber cheaper for everyday cars. This way, it can be used in more vehicles.

Hi, I’m Fernando Pham, and welcome to WhyDetails.com! I’m from San Francisco, and I love exploring questions and sharing answers through my blog.